Railroad

WASTED TIME & RESOURCES DURING RAILROAD TUNNEL MAINTENANCE

The Problem with Tunnel Work Today

Conducting regular maintenance on one of the thousands of railroad tunnels across the country is no simple or minor task. It can take days to complete regularly scheduled maintenance on a single tunnel, even with a full team of workers alongside an entire fleet of track equipment. One of the challenges to complete tunnel maintenance timely and efficiently is the mandatory work delays. These are often caused by the carbon monoxide and other harmful airborne toxins put off by the combustion engines in use during tunnel work.

Once the concentration of carbon monoxide or any other hazardous by-products put off by gasoline/diesel powered equipment reaches unsafe levels, work must be temporarily shut down until the detected toxins return to a safe level. These temporary shutdowns often happen numerous times during the single workday and even when they last only briefly, can still cost tens of thousands of dollars in unused labor.

ELIMINATE WASTE – MAINTAIN EFFICIENT WORK FLOW

No More Temporary Shutdowns

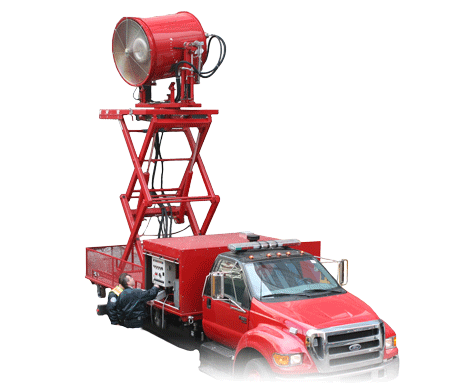

In evaluating the problem and attempting to find a solution, there are two immediate directions to pursue: Either eliminate the production of hazardous combustion engine by-products, or remove them completely before they reach dangerous levels, and the Tempest Mobile Ventilation Unit or MVU® is capable of doing just that; rapidly ventilating any size tunnel of virtually all hazardous fumes and gases, and immediately replacing them with clean, fresh air.

During a number of recent tests in which a Tempest MVU® was used during typical tunnel maintenance operation, dangerous carbon monoxide and other undesirable chemicals were reduced to zero PPM and remained at that level for as long as the MVU® remained running. This highly effective and efficient method of tunnel ventilation entirely eliminates the need for temporary shutdowns, saving enough time and money for the unit to pay for itself.

PROUD MEMBERS OF: